RIYADH\BEIJING, May 17 (Xinhua) -- A yellow-green metro train is running southeast on a light railway near the sacred city of Mecca through a whirlwind of flying sand and unbearable heat.

On a May day in west Saudi Arabia's desert valley, the bright, spotless train body looks like a breeze of light air. The eye-catcher is attributed to the machine washer designed and manufactured by CHSR, a Chinese supplier of solutions and products for the operation and maintenance of rail transit systems.

FIRST OVERSEAS ORDER

"With a relatively solid rail transit system and a sound relationship with China, Saudi Arabia is an essential part of CHSR's Mid-East strategy," said Li Xinzheng, market director of the China High-Speed Railway Technology Co. Ltd (CHSR).

The train washer for the Mecca Metro was CHSR's first overseas order, tailor-made for the 18-km transit line completed in late 2010 by Chinese construction and engineering company CRCC. The transit line connects major holy sites of the annual Hajj pilgrimage.

"As common engines are vulnerable to sand and dust, CHSR applies a full-enclosure design to the washers for the windy and dusty Mecca," Wu Jianwei, director of CHSR' s overseas business, told Xinhua.

What's more, a water recycling system was specially developed to save water in the desert area, he said.

Furthermore, the washing machine is capable of adjusting its brushes to the train's surface, reducing damages to the paint, windshields and wipers, while it meets European standards in endurance, emissions and efficiency.

The train washer, which is also being used in Singapore, has become a best seller for the Beijing-based railway tech company, with one variety for high-speed trains taking up a 90 percent share in the domestic market.

"Though the train-washing business originated in Germany and developed in the United States and European countries, such as Spain, the Chinese standards for bullet trains are currently higher than theirs," Wu stressed.

A BOOST OF BELT AND ROAD

The train washer is only part of CHSR's 400-plus product line, which also includes products and solutions for operating and maintaining the locomotive, rolling stock signal and power supply systems, rail transit, and depot.

More than an equipment supplier, the company, which has nine subsidiaries, also offers an overall solution to individual or multiple transit lines. It also aims to make breakthroughs in big data and industrial services in the coming years.

While Chinese flagships CRCC and rolling stock manufacturer CRRC are visible giants in foreign business, Li said CHSR is an invisible giant abroad.

Market research shows the maintenance of overseas urban railway transit is valued at around 140 billion U.S. dollars during the 2016-2020 period, with a great potential to be multiplied in the future.

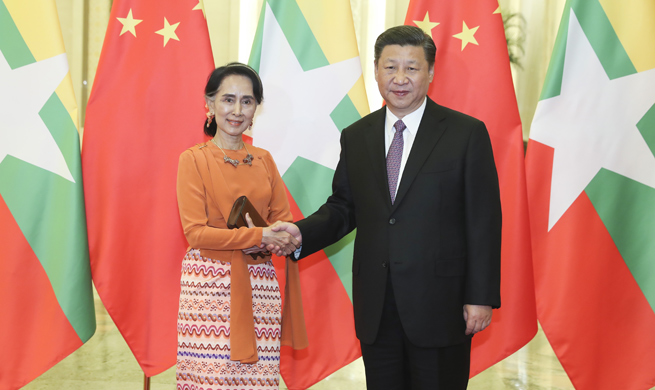

As the China-proposed Belt and Road Initiative keeps making progress, CHSR's overseas business is growing rapidly, said Wu, noting that countries along the Silk Road routes are among the major contributors to the market.

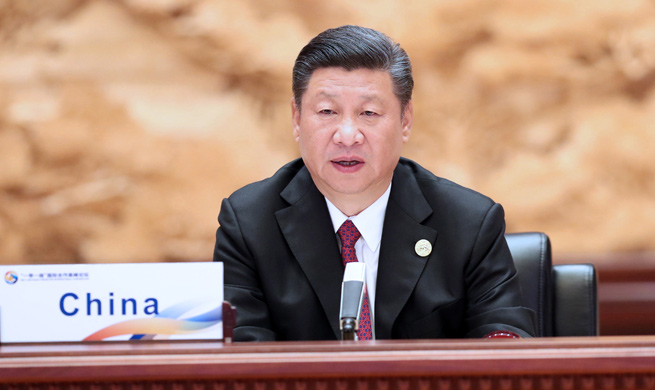

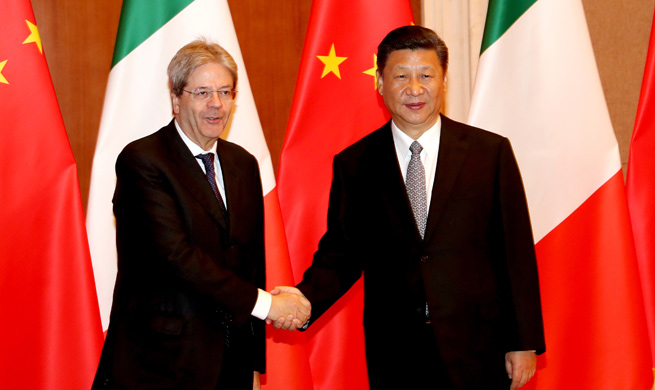

China's world's leading high-speed railway products, which represent the top standard of the Chinese manufacturing are a "name card" of the industry, a major topic between China and other countries.

With access to more potential partners abroad, the sector of trail transit has been one of the biggest beneficiaries of the Belt and Road Initiative, Wu said. "CHSR will expand its global footprint by taking good advantage of those opportunities."

GROWING BY LEARNING

In addition to the Middle East market, CHSR has managed to stretch its reach to Europe, North America, Southeast Asia and Russia by acting as an equipment supplier for China state-owned enterprises working on foreign contracts or partnering with foreign counterparts on their local projects.

But their global appearances did not come easily. Wu cited a train-set washer program for Singapore's rail transport that should have been completed within a half-year period but took around two years before it was operational due to high labor and material cost.

Singapore's labor law requires foreign companies to employ and use only local staff, while some of the materials used for the project must be bought locally.

Therefore, local partners play a key role in project execution as they are responsible for installing equipment, running tests, and training workers, as well as maintenance and other after-sale service, Wu elaborated.

What CHSR sells is not a disposable product but one that needs continuous care, he said. "Localization is actually a win-win result that will not only benefit CHSR but also create more jobs for local residents."

As foreign governments raise their awareness of environmental protection, high tech-driven companies like CHSR are very popular in their markets, Li said. "What we need to do is to clear any doubt with our top-quality products and services."

?

?